Increase the Durability and Lifespan of Your Metal Parts

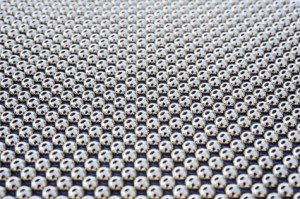

Vibratory finishing is smoothing metal parts by leveraging the force of gravity. The parts that need finishing are placed into a vibratory machine’s tumbler tub. The machine then vibrates the parts, water, and abrasive media to achieve the desired finish. The process’s length depends on the number of parts, roughness, and size. Vibratory finishing is also safe for fragile parts.

Vibratory finishing is smoothing metal parts by leveraging the force of gravity. The parts that need finishing are placed into a vibratory machine’s tumbler tub. The machine then vibrates the parts, water, and abrasive media to achieve the desired finish. The process’s length depends on the number of parts, roughness, and size. Vibratory finishing is also safe for fragile parts.

RP Abrasives is a leading New England metal finishing company that offers quick turnarounds on our mass finishing services. Since our company was founded in 1996, we’ve made remarkable strides in our knowledge of vibratory metal finishing. We also specialize in high-energy mass finishing, which involves polishing parts using centrifugal force.

Our Vibratory Mass Finishing Equipment

At our New Hampshire facility, we have an assortment of vibratory mass finishing equipment that is used for jobs large and small, including:

- One 3-cubic-foot Torx vibratory bowl

- Two 3-cubic-foot Sweco vibratory bowls

- One 3-cubic-foot Ultramatic vibratory bowl

- Two 5-cubic-foot Ultramatic vibratory tubs

- One 1-cubic-foot Almco vibratory tub

- Various sizes and shapes of plastic and ceramic medias

Request a Vibratory Finishing Quote from RP Abrasives

If you’re in the market for vibratory polishing of stainless steel, look no further than RPA. For a zero-cost, no-obligation tumble finishing consultation, fill out the form below to request a free quote! If you have questions about our finishing services, please call us at (603) 335-2132 or contact us online.